Understanding Your Car’s Master Cylinder

When it comes to the braking system of your car, the master cylinder plays a crucial role. It is an essential component that ensures the proper functioning of your vehicle’s brakes. In this article, we will take a closer look at the master cylinder, its purpose, and how it works.

What is a Master Cylinder?

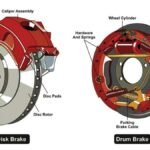

The master cylinder is a hydraulic device that converts the pressure applied to the brake pedal into hydraulic pressure. This hydraulic pressure is then transmitted to the brake calipers or wheel cylinders, which in turn apply the necessary force to stop the vehicle.

How Does it Work?

The master cylinder consists of a reservoir, a piston, and a series of valves. When you press the brake pedal, it pushes the piston in the master cylinder. This action creates pressure in the brake fluid, which is stored in the reservoir. The pressure is then transmitted to the brake lines, causing the brakes to engage.

The master cylinder also has a series of valves that control the flow of brake fluid. These valves ensure that the pressure is evenly distributed to all the wheels of the vehicle. They also prevent the brake fluid from flowing back into the master cylinder when the brake pedal is released.

Signs of a Failing Master Cylinder

Like any other component in your car, the master cylinder can develop issues over time. Here are some signs that indicate a failing master cylinder:

- Soft or spongy brake pedal

- Brake fluid leaks

- Brake warning light on the dashboard

- Loss of brake pressure

- Difficulty in applying brakes

If you notice any of these signs, it is crucial to have your master cylinder inspected and repaired by a qualified mechanic.

Maintenance and Care

To ensure the longevity and proper functioning of your car’s master cylinder, regular maintenance is essential. Here are a few tips to keep in mind:

- Check the brake fluid level regularly and top it up if necessary.

- Inspect the brake lines and hoses for any signs of wear or damage.

- Replace the brake fluid as recommended by the manufacturer.

- Have the master cylinder inspected during routine brake service.

By following these simple maintenance practices, you can help prevent potential issues with your master cylinder and ensure the safety of your vehicle.

What is a Power Brake Booster?

The first power brake booster was invented in 1927 by Belgian engineer Albert Dewandre, and by 1928, Pierce-Arrow was the first car company that used a power booster system. The power booster uses the difference between engine vacuum, and atmospheric pressure, to help you press the brake pedal.

Because drum brake systems used in older cars took less effort to operate, it wasn’t until the advent of the disc brake that it was necessary to use a power brake system. Although vacuum brake boosters were available from the 1930s on many cars, they didn’t become standard equipment until much later.

Power disc brake systems are more difficult to operate and take more force to depress the pedal. A large diaphragm inside the booster has negative pressure on one side, and when you press the pedal, atmospheric pressure it let into the other side. The beauty and simplicity of this system has kept it much the same for 80 years, and it even works for several stops if the engine were to die suddenly.

What is a Proportioning Valve?

The proportioning valve reduces the pressure to the rear brakes, because the rear brakes require less force than the front brakes. In race cars this is often adjustable by the driver while driving, to account for the change in weight as they burn off fuel and wear the brakes and tires. The amount of brake force that can be applied to a wheel without locking it depends on the amount of weight is on the wheel, which is why most pick-up trucks have a valve which adjusts rear braking force depending on payload.

Factory proportioning valves are often combination valves, incorporating the residual valve, metering valve, and pressure differential switch into them. They are typically mounted just below the master cylinder at the firewall.

What is a Residual Valve?

Vehicles that have disc brakes in the front and drum brakes at the rear require a residual valve to keep the brake drum shoes ready to be applied. Disc brakes are always in contact with the rotor, but with the drum brakes, they are slightly pulled away from the drums by the mechanical springs, and need 10 psi to counter the force of the springs. By having the rear brakes engage before the front brakes brakes, the vehicle has more stability while braking and is less prone to nose dive

Some older cars, trucks, and vans with the master cylinder under the floor, use a 2 psi residual valve to keep fluid from draining back out of the lines to the wheels. With a firewall-mounted master cylinder, gravity provides that residual pressure.

What is a Pressure Differential Switch?

As long as the pressure in both brake circuits is the same, the piston in the pressure differential switch will stay centered in its cylinder. But if one side develops a leak, the pressure will drop in that circuit, forcing the piston off-center and closing off the side that has failed.

This closes a switch, which turns on a dash warning light in the instrument panel of the car.

In Conclusion

The master cylinder is a vital component of your car’s braking system. Understanding its purpose and how it works can help you identify any potential issues and take the necessary steps to maintain it properly. Remember to pay attention to any signs of a failing master cylinder and seek professional help if needed. By taking care of your master cylinder, you are ensuring the safety and reliability of your vehicle.